Gas Brooders vs Bulb Brooders: Which Is Better for Poultry Farmers?

Brooding is one of the most critical stages in poultry farming. Proper heat ensures chicks grow healthy, reduces mortality, and improves feed efficiency.

Kenyan farmers often face a choice between gas brooders and bulb brooders. Each has its advantages and disadvantages. This guide explains the differences, benefits, and considerations to help you decide which is best for your farm.

What is a brooder?

A brooder is a device that provides heat to young chicks during their first 3–6 weeks.

Without a proper brooder, chicks may suffer from cold stress, poor growth, and high mortality. Brooders can be powered by electricity, gas, or even charcoal. In Kenya, gas and bulb (electric) brooders are the most common.

Understanding bulb brooders

Bulb brooders use electric bulbs to provide warmth. They are simple, affordable, and suitable for small flocks.

Advantages:

-

Low initial cost for small-scale farmers

-

Easy to set up and use

-

Can provide sufficient heat for 20–50 chicks in a small area

Disadvantages:

-

Limited coverage for larger flocks

-

Electricity is required, which may be unreliable in rural areas

-

Heat distribution may be uneven

-

Frequent bulb replacement may be needed

Bulb brooders are ideal for hobby farmers or small-scale poultry operations where electricity is stable.

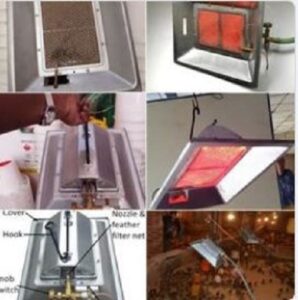

Understanding gas brooders

Gas brooders use LPG or natural gas to generate heat. They are widely used by commercial poultry farmers in Kenya.

Advantages:

-

Provide consistent, even heat for large flocks

-

Economical for medium- to large-scale farms

-

Lower risk of power outages affecting brooding

-

Adjustable flame for precise temperature control

Disadvantages:

-

Higher initial cost compared to bulbs

-

Requires careful handling of gas for safety

-

Slightly more complex setup

Gas brooders are preferred for farmers who run larger poultry operations and need consistent temperature control.

Key differences between gas and bulb brooders

| Feature | Gas Brooder | Bulb Brooder |

|---|---|---|

| Heat source | LPG or natural gas | Electric bulb |

| Suitable flock size | Medium to large | Small to medium |

| Heat consistency | High, even distribution | Moderate, uneven for large flocks |

| Initial cost | Higher | Lower |

| Operating cost | Moderate | Low (depends on electricity) |

| Safety | Requires gas handling | Minimal (risk of fire if mishandled) |

Impact on chick health and growth

Proper brooding reduces stress, improves feed intake, and reduces mortality.

-

Gas brooders provide stable temperature, which supports uniform chick growth and reduces disease risk.

-

Bulb brooders may create hot spots or cold areas, causing some chicks to huddle or scatter.

-

Studies in Kenyan poultry farms show that consistent temperature reduces coccidiosis and respiratory diseases, which are common in early chick life.

Cost considerations for Kenyan farmers

When choosing between gas and bulb brooders, consider both initial cost and operating cost:

-

Bulb brooder: Cheaper upfront, but may not scale well. Electricity reliability is a concern in rural counties.

-

Gas brooder: Higher upfront cost, but cheaper for large flocks in terms of heat efficiency and reduced chick losses.

For small flocks (50–200 chicks), bulb brooders may be sufficient. For larger flocks (500+ chicks), gas brooders are more cost-effective in the long run due to lower mortality and better growth rates.

-

Practical tips for brooder use

-

Always monitor chick behavior to ensure correct temperature.

-

Place feeders and drinkers nearby but not directly under the brooder.

-

Use a thermometer at chick level for precise measurement.

-

Ensure proper ventilation to prevent humidity buildup without losing heat.

-

Keep litter dry to maximize insulation and reduce disease risk.

Combining brooders with other poultry equipment

A brooder alone is not enough. Proper feeding and drinking systems are critical for chick survival.

-

Use chicken feeders and drinkers from trusted suppliers like Mkulima Jovial to ensure chicks can eat and drink comfortably.

-

For larger farms, pairing gas brooders with automated watering systems reduces labor and improves consistency.

Safety considerations

-

Gas brooders require proper installation, good ventilation, and safe gas handling to prevent accidents.

-

Bulb brooders require fire-safe placement and regular bulb checks.

-

Always monitor brooding equipment during the first few weeks, especially in rural areas where electricity or gas supply may fluctuate.

Which brooder is best for Kenyan farmers?

The choice depends on flock size, farm scale, and resources:

-

Small-scale farmers: Bulb brooders are affordable, easy to manage, and ideal for 20–100 chicks.

-

Medium- to large-scale farmers: Gas brooders provide consistent heat for hundreds of chicks, reduce mortality, and improve growth rates.

-

Consider hybrid solutions: using bulbs for small batches and gas for larger or commercial batches.

Conclusion on how Gas brooders vs bulb brooders for poultry farmers

Both gas and bulb brooders have their place in Kenyan poultry farming.

-

Bulb brooders are suitable for small-scale farmers with low initial investment.

-

Gas brooders are better for larger operations, providing stable temperature, reduced chick mortality, and improved profitability.

Using the right brooder, together with proper feeders, drinkers, and litter management, ensures chicks grow healthy, reduces disease, and sets the foundation for a successful poultry farm in Kenya.